At Embedded Technologies (ETE), we understand that food processing is one of the most demanding sectors when it comes to both safety and efficiency. With strict regulations and the ever-present risk of contamination, the need for reliable and specialized technology has never been greater. Industrial PCs are quickly becoming the backbone of modern food processing, ensuring operations run smoothly while adhering to safety and regulatory standards.

As food processing facilities become increasingly automated, choosing the right technology is essential. Industrial PCs, such as rugged embedded systems and high-brightness display screens, are critical components for ensuring seamless operations even in the harshest conditions. But why exactly do industrial PCs excel in food processing, and why are they a necessity rather than a luxury?

Table of contents

- Why Standard PCs Fall Short in Food Processing

- The Role of Industrial PCs in Ensuring Food Safety and Efficiency

- The GENE-ADP6 Embedded Board: A Perfect Companion for Food Processing Automation

- How ETE’s Embedded Solutions Are Optimized for Food Processing

- Case Study: How Embedded Solutions Transformed Operations at Tetrapac

- Unlock our free eBook

- Get in touch

Why Standard PCs Fall Short in Food Processing

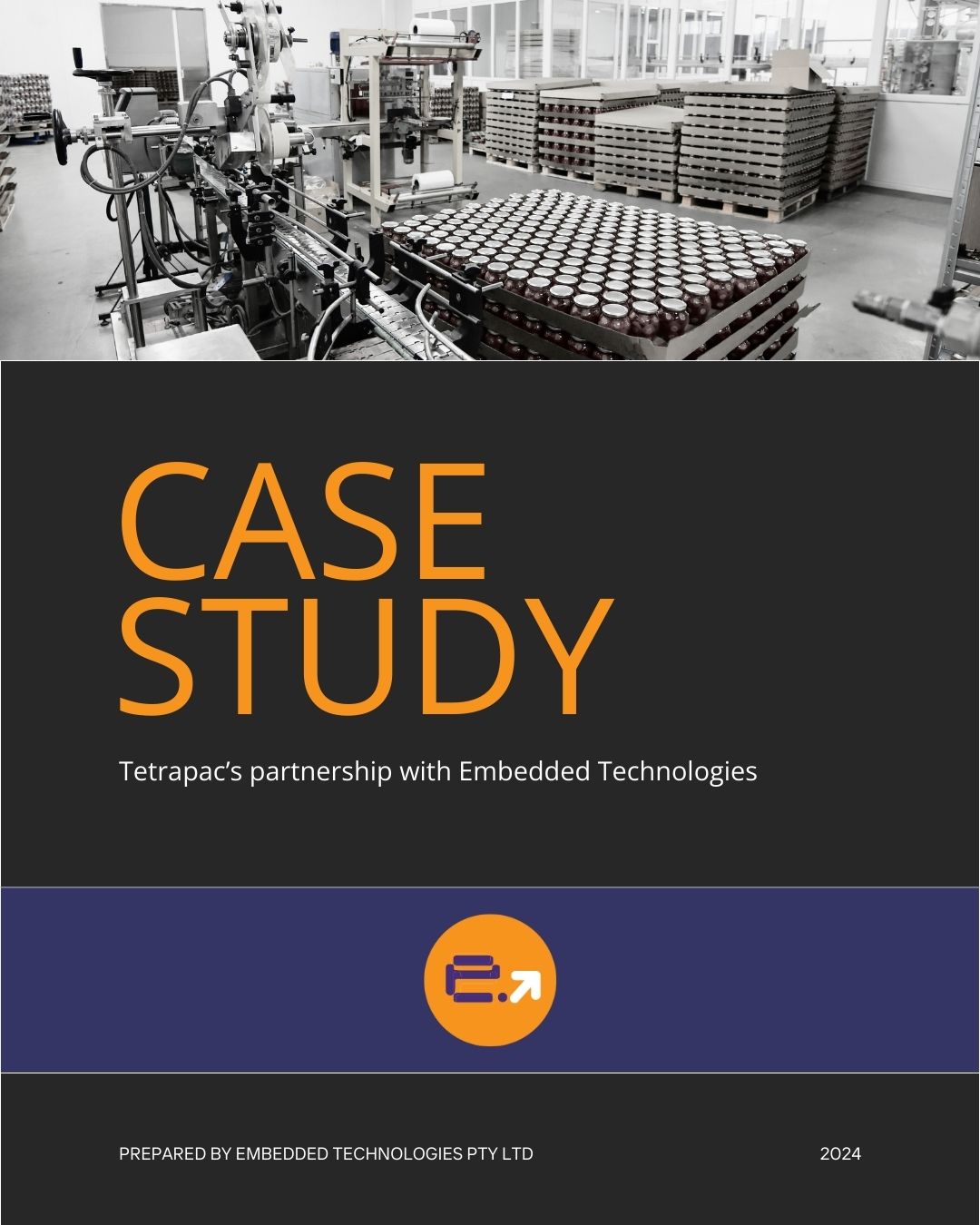

Food processing environments are harsh. From constant exposure to moisture, high-pressure washdowns, and temperature extremes, standard PCs and monitors simply aren’t built to handle the demands. In such conditions, using conventional equipment leads to frequent breakdowns, shorter lifespans, and even contamination risks—none of which are acceptable when food safety is at stake.

When standard computers come into contact with water, dust, or extreme temperatures, they can easily corrode, malfunction, or contribute to contamination risks. This is where specialized industrial-grade PCs and embedded boards step in to bridge the gap.

The Role of Industrial PCs in Ensuring Food Safety and Efficiency

Specialized industrial PCs, such as ETE’s Rugged Embedded BOX PCs and high-brightness display screens, are designed to withstand the rigors of food processing environments. Not only are they durable, but they also help streamline processes, improve traceability, and provide real-time monitoring—all while complying with stringent food safety regulations.

Here are some key ways industrial PCs improve food processing:

- Durability in Harsh Environments: Unlike standard PCs, industrial PCs are designed to operate in extreme conditions. ETE’s Rugged Embedded BOX PCs are built to thrive in environments where water, dust, and temperature fluctuations are the norm, reducing the risk of equipment failure and contamination.

- Automation and Efficiency: Industrial PCs ensure precision in automation, allowing for accurate product tracking, assembly, and distribution. Real-time data access enhances efficiency, minimizes human error, and helps facilities meet production targets.

- Enhanced Compliance and Safety: Industrial PCs help businesses stay compliant with food safety regulations. These systems are designed to withstand frequent cleaning, high-pressure washdowns, and chemical exposure, ensuring no risk of contamination while maintaining continuous operation.

- Long-Term Cost Savings: Investing in rugged, specialized industrial PCs results in long-term savings. These systems not only last longer but also reduce downtime and maintenance costs, providing greater ROI compared to standard PCs.

The GENE-ADP6 Embedded Board: A Perfect Companion for Food Processing Automation

While industrial PCs play a vital role in harsh environments, embedded boards such as the GENE-ADP6 are crucial for powering specific systems within the food processing workflow. This high-performance embedded board integrates seamlessly into existing automated processes, driving critical functions such as data acquisition and real-time monitoring.

The GENE-ADP6 enhances the overall automation process by offering powerful performance while being compact enough to fit into smaller spaces. This embedded board ensures that food processing systems operate smoothly and reliably, complementing industrial PCs in creating an efficient and compliant production environment.

How ETE’s Embedded Solutions Are Optimized for Food Processing

ETE offers a range of embedded technology solutions tailored to the needs of the food processing industry. Our Rugged Embedded BOX PCs and high-brightness displays offer unparalleled performance, even in the most demanding environments. Featuring extended temperature support and corrosion-resistant enclosures, these systems can be integrated into any facility while ensuring hygiene and operational efficiency.

Our embedded solutions:

- Seamlessly integrate with automated processes, improving production accuracy and efficiency.

- Deliver real-time data tracking, helping facilities manage and monitor operations with precision.

- Resist corrosion and water damage, ensuring long-lasting performance without risking food contamination.

Case Study: How Embedded Solutions Transformed Operations at Tetrapac

Take Tetrapac, for example. As a leading provider of food processing equipment, they integrated ETE’s GENE-ADP6 embedded board into their processing lines. This allowed them to automate key operations, enhance monitoring, and maintain strict hygiene standards. The result? A significant improvement in efficiency and reduced downtime, all while ensuring compliance with food safety regulations.

Unlock the Full Story: Download Our Free Ebook

By integrating advanced embedded technology into your facility, you can take your food processing operations to the next level. Contact ETE today to explore how our industrial PCs and embedded solutions can enhance your processes, improve safety, and ensure compliance with food industry standards.

If you’ve found this exploration of embedded computing intriguing, you’ll want to dive even deeper into the world of modern embedded computers. Our free ebook, “Unlocking Innovation: A Guide to Modern Embedded Computers,” is your comprehensive guide to understanding the technology, its applications, and the emerging trends that are shaping the future. Inside the ebook, you’ll find detailed insights, real-world case studies, and expert perspectives that will expand your knowledge of embedded computing. Don’t miss out on the opportunity to unlock innovation in your projects.

Want to have a conversation about your business’s embedded computing needs?

Get in touch with us!