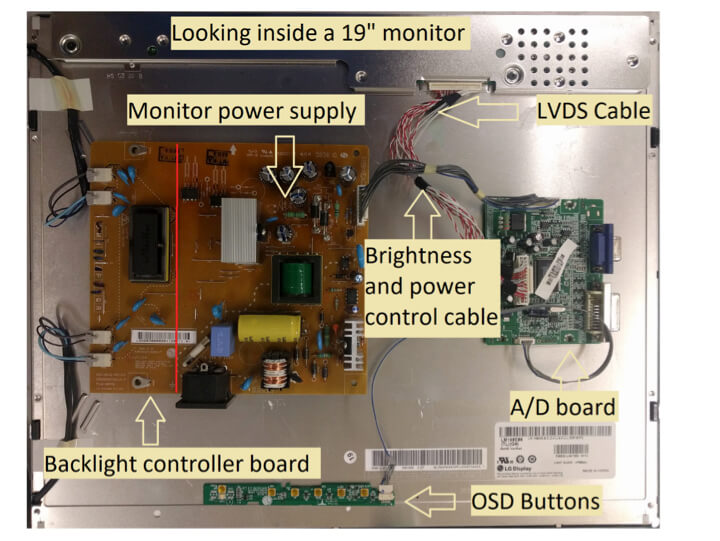

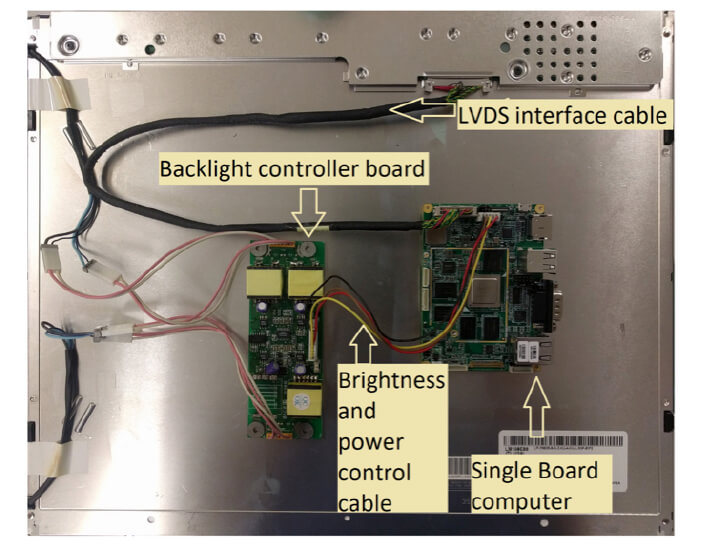

One of the truly neat and unique features of industrial Single Board Computer (SBC) is ability to drive a high resolution LCD panels via the on board LVDS (low voltage differential signalling) interface, giving a superior image quality when compared to a standard monitor. There are many technical advantages in this method and can be easily be seen in pictures below: – comparing what’s inside a stand monitor and using a single board computer to drive a LCD panel.

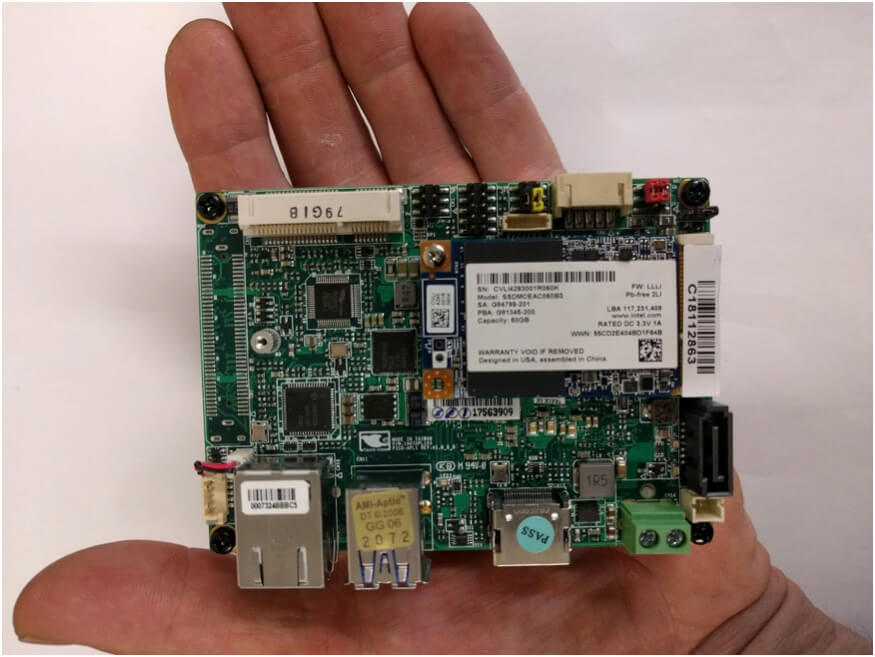

In the following guide, will provide insight on how to go from this:

To the simplicity of a single board driving a LCD panel:

For every Display monitor to work, it needs to process the video inputs from a computer via a variety of inputs such as VGA or HDMI, then best guess how the image is to be displayed and converts the image a LCD panel can understand via the LVDS interface. Operator tweaking is sometimes needed via the OSD control/button to achieve the ideal image. The heart of the LCD monitor, the “A/D board” (Analogue to digital) has two primary functions, convert the image and control the backlight.

A good example of comparing the quality of image, compare the same image on monitor and a laptop (laptops use LVDS to connect directly the built in LCD panel). Laptop screens images are crisp whilst a display monitor can look fuzzy.

Using a single board computer to directly drive the panel via LVS doesn’t best get the panel resolution, it knows the exact resolution of the panel and displays images in crisp and clear. All functions such as LCD controls brightness, contrast, colours etc. are controller by the application and/or operating system.

Whilst SBC can support other direct interface methods such as TTL, I2C, SPI or parallel or serial more commonly used on smaller low definition displays. Single boards stand out with the ability to support the 1000’s of LCD panel makes and models commonly used in monitors, infotainment systems and industrial high brightness displays.

So, how do you interface a single board computer to a LCD panel via its LVDS interface?

Very easily!

First a super quick guide to understanding the two basic parts of a LCD panel. The LCD display and backlight.

LCD display generate the image from the signal received through the LVDS input and displays does its magic and creates an image on the panel.

Backlight as the name entails provides the back light, typically a set of LEDs at the back of the LCD panel to project the image.

Think of the relationship like a super 8 projector, the light in a projector is the backlight and the film is LCD display. Both parts of the LCD are controlled and powered independently. But like a super 8 projector both are needed to display the image!

Here are the main points needed to interface and connect to a LCD panel:

LVDS interface

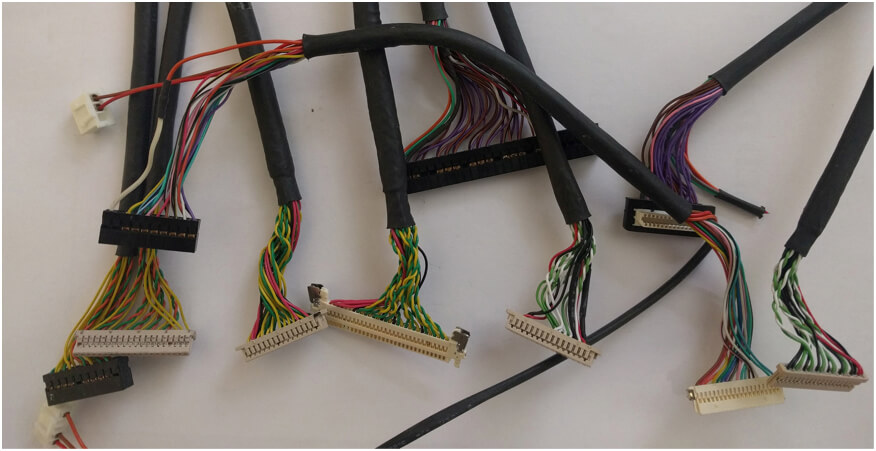

LVDS connectors used on LCD panels, come in different size and shapes and are manufacturer-specific, all do follow a reasonably common LVDS panel signal standard and sometimes pinout. The hardest part is matching the pinout between the LCD panel and the single board computer. Embedded Technologies has a range of LVDS cables available or can design a cable to suit your requirements.

LCD panel resolution and configuring:

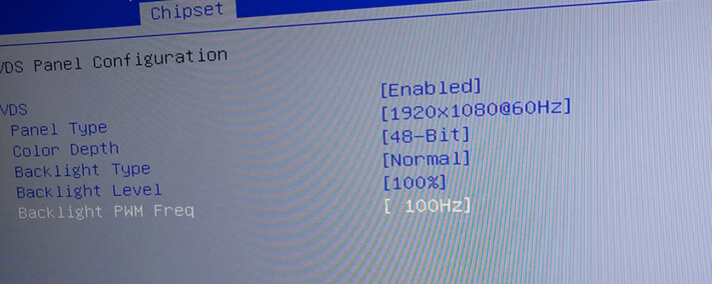

Depending on the resolution and specification of the LCD panel, SBC computer will need either 18/24/32/48 bit single or dual channel LVDS output. The amount of flexibility in resolution supported by the SBC is dictate by the chipset, as an example the PICo-XXX supports a range of panel resolution from 640 x 480 up to 1800 x XYZ is found on higher end Industrial single board computer. Options can be configured via the BIOS setup screen.

LVDS panel driving voltage

3.3V or 5V, set via a jumper on the SBC. Refer to the LCD manufacturers specifications as to which driving voltage is required. As a word of warning, setting the wrong voltage can damage the LCD panel especially if it’s a 3.3V and jumpered for 5V!

Backlight driver board

All panels’ need some type of backlight driver board, smaller panels in particular panels with LED backlight may the electronics embedded inside the panel or on larger higher brightness panels have external driver boards.

They all need require: Power, On/Off and brightness control. Depending on the specification of the controller, brightness can be adjusted via PWM (pulse width modulation) or analogue voltage range.

To view our full range of Single Board Computers (SBC’s) that support this feature. For more information please visit: Embedded Boards

Power and GND.

12V is commonly used. Current requirements vary, from Sub 1 amp upwards, all depends on size and brightness of a panel. As an example a 6.4” LED backlight display with 300Nit brightness uses XYZ or a super bright 24” 1500 NIT brightness panels requires 4+amps. Ensure you’re power supply is designed to deliver the necessary currents to drive the backlight. For the higher current displays, supply power directly to the display.

On/Off control:

Typically 3V for on and 0V for off.

Brightness control:

Ideally signal from the SBC can provide an analogue or PWM (pulse width modulation) output allowing the ability to dim the display.

Still sounds overwhelming, seriously it’s not. The hardest part is getting the right cables to match the panel, Embedded Technologies can provide you with a panel specific connector, send the panel specs through and will match a suitable cables to drive both the LVDS and backlight.

As for the SBC, view our full range, a good example PICO-APL1 wide temperature single board computer, right off the shelf supports up to 48BIT dual-channel LVDS and 3840 x 2160 resolution, in addition, can power the backlight directly via the onboard LCD backlight control. The neat thing once connected right, brightness control and switching the LCD on/off can be directly controlled by the operating system. And it all fits neatly in the palm of your hand, how simple clean and neat is that! PICO-APL.

LCD Watchdog controller

What’s worse blank screen or this…

For more information get in touch with us.